Transforming Quality Management for the Entire Export Assembly Line

Empowering Quality Across the Export Line

The Challenge: Managing the quality of an entire assembly line for export can be a daunting task. Ensuring consistency, transparency, and visibility of quality data across the operation was a significant challenge. Manual quality checks were prone to human error, leading to a high percentage of non-conforming or faulty parts reaching customers.

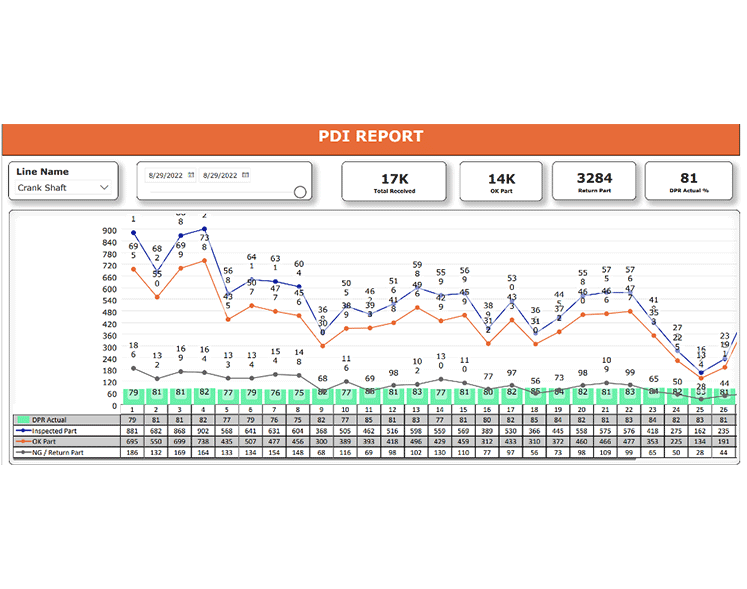

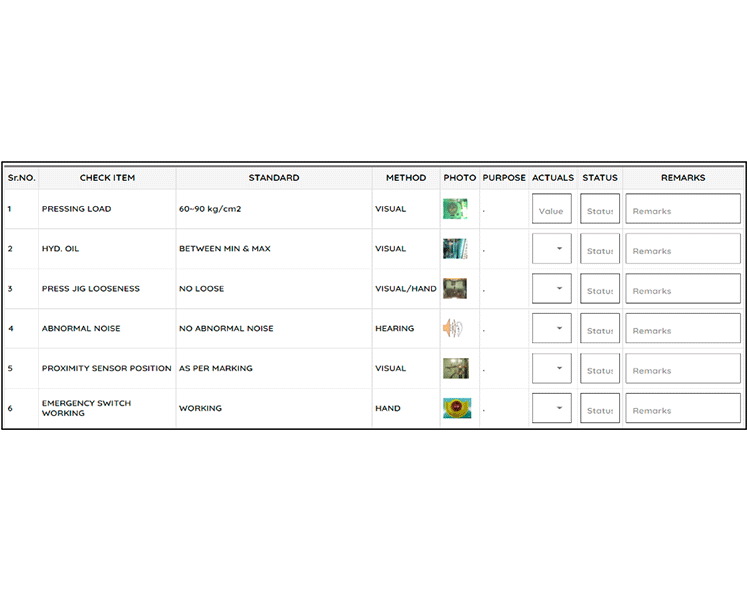

Our Solution: Cymbeline implemented a robust Quality Management System that revolutionized the entire assembly line. Our solution introduced a stable Pre-Dispatch Inspection system, offering precise control over quality management.

Key Achievements:

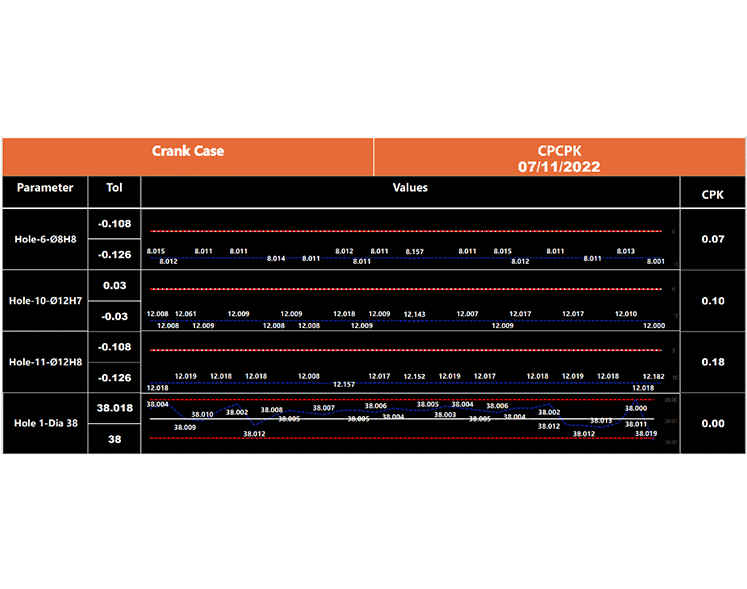

- Streamlined Data Recording: We provided a comprehensive recording facility for process parameters and measured parameters of all parts processed through 60 different machines. This automated data collection minimized errors, ensuring the quality of every component.

- Visibility and Transparency: Our system ensured the visibility, transparency, and easy access of data to management. Real-time insights into quality metrics empowered decision-makers to take proactive actions.

- Reducing Non-Conformities: The results were astounding. Through our Quality Management System, the company achieved a remarkable 90% reduction in non-conforming or faulty parts reaching customers. This dramatic improvement not only enhanced customer satisfaction but also reduced operational costs.

Outcome: Cymbeline’s Quality Management System brought a transformative change to the entire assembly line, ensuring consistent quality, reducing errors, and saving costs. By harnessing the power of data and automation, we helped our client exceed quality standards and boost customer confidence.

Join us in our commitment to delivering excellence through quality management. Let us help you achieve similar results and set new standards in your industry.